At Stanwell Corporation’s Meandu Mine, the EX5500-5 continues to have very high availability – even at 80,000 working hours. This has been possible not just due to equipment performance, but also due to Hitachi Construction Machinery Australia’s support and the customer’s loyal cooperation. Here the experience of two representatives from Meandu Mine to reflect on their favorite memories of the EX5500-5.

Stanwell Corporation Limited

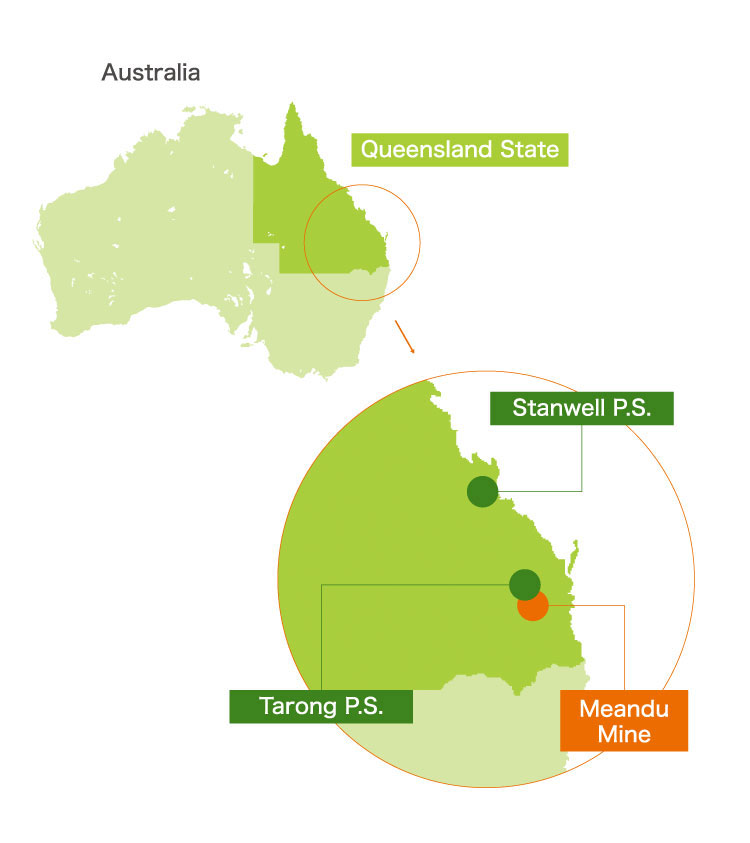

Stanwell Corporation is a Queensland government-owned corporation and the state’s largest electricity generator, owning and operating a portfolio of electricity generation assets in Queensland.

Stanwell Corporation supplies resources to two of the newest and most efficient coal-fired power stations in Australia – Stanwell Power Station in Rockhampton, and Tarong North Power Station in the South Burnett.

Stanwell Corporation sells electricity directly to large commercial and industrial customers along the eastern seaboard of Australia.

Stanwell Energy is an accredited GreenPower provider for its current and potential customers. Stanwell Energy offers clients the option to make a positive contribution to the environment, by sourcing some or all of their electricity needs from renewable energy sources.

Business beginnings with Hitachi Construction Machinery (HCM)

The relation between HCM and Meandu mine, currently owned by Stanwell, dates back to 1987 when Hitachi Construction Machinery delivered the first UH801 hydraulic excavator (160 tons). Prior to this, three UH801 loading shovels were working in Curragh mine, located near current Stanwell Power stations; this had already established a good reputation for Hitachi excavator in Queensland.

At this time overburden was extracted with a dragline and spoiled to spoil dumps. With the help of rear dump trucks, the excavator loaded out coal to the coal plant, and removed overburden and inter burden to waste dumps. The high availability of the UH801 was evaluated by the user, and as a result of two EX3500 (325 tons) excavators, the larger model of the new series, was purchased.

History of Meandu Mine

Meandu Mine currently has four working pits and is central to Stanwell’s long-term plan for the Tarong power stations site.

Jacob and Jim on Meandu’s legendary EX5500-5

With an impressive near 80,000 operating hours logged, Hitachi EX5500-5 is the longest-running machine currently active at Meandu Mine. Commissioned to the site in 2006, the team at Meandu has a special fondness for the EX5500, which has become known for its ability to work through the toughest situations. Despite being 13 years old, it remains one of the most reliable machines at the site.

Acting Site Manager, Jacob Orbell joined Meandu Mine in 2012 and has been working alongside the EX5500 ever since. With a background in mining engineering, Jacob began his career in Western Australia. He went on to work in the explosives industry and then in oil shale, before coming to Meandu.”Since being at Meandu I’ve worked across a number of roles including the Technical Manager, the Environmental Manager, and now Site Manager,” Jacob said. “Since I began at Meandu, I’ve dealt with HCM’s products on the purchase of two large mining excavators (EX8000 and EX5500), the EH5000 truck fleet, two Bell service trucks, and the Wenco Fleet Management System. I’ve had a lot to do with HCM over the years.” The EX5500 is a prized machine thanks to its proven ability to keep the mine running through any challenge.

“If we have tighter material to excavate, the EX5500-5 is the one we send to load it out with its great breakout force,” …”It’s always been our ‘backup plan’ for when things don’t go to plan.”

When looking back on challenges the EX5500-5 has overcome, Jacob is impressed with one memorable event in particular. “We faced an instance where without EX5500-5 we faced a delay in our mine plan, which would have meant parking up dragline production,” recalls Jacob. Jacob and the team sent another machine into the area to remove the dirt initially, but it was having trouble as the conditions were extremely tough. “The EX5500-5 was sent to the area to excavate that material, and it worked admirably and managed to get through it.”

Jacob’s favorite thing about the EX5500-5 is the power it has. “This particular machine has an amazing amount of breakout force compared to the other excavators on site, and our excavator operators always talk about it being the best excavator on site.”

“Even right up to the nearly 80,000 hours it has reached, it’s still operating around 90% availability the whole time which is fantastic. If it wasn’t achieving that kind of reliability, it would have been replaced a long time ago.”

“It has been a very pleasing experience to have the EX5500-5; it has been such a reliable machine for us.” Jacob’s high regard for Hitachi machinery doesn’t stop at the EX5500. A highlight of his time at Meandu has been getting Hitachi’s EX8000-6 excavator and EH5000AC-3 truck fleet on site. These machines created a step-change in the cost of Meandu’s waste movement, bringing it down considerably. This efficiency increase meant they could run just three trucks and shovel fleets instead of four. When Jacob looks back on Meandu’s relationship with HCM, he feels a sense of pride in how both organizations have been able to work together.

“I think a highlight of Meandu’s relationship with HCM is that we’ve always been able to come up with mutually beneficial arrangements,” Jacob said.”We’ve been able to see the needs of a situation from each other’s perspectives and this has allowed us to achieve great outcomes together. Meandu has a history of purchasing first-of-a-kind Hitachi machines, buying the first-ever EX8000-6 in backhoe configuration excavator, and the first EH5000AC-3 trucks that came into Australia. Jacob says making these decisions has paid off for Meandu with the machines being well supported by HCM. “The machines have always performed as expected, in fact, they have often performed above our expectations. In terms of machine availabilities, generally, we’re always sitting above our taget mark, and some of our Hitachi excavators are over our target. We’re very pleased with the availability of the fleet.”

Working closely alongside Jacob Orbell is Jim Young, Meandu’s Asset Manager of Mining. Having worked at the site since 1978, Jim has a longstanding relationship with HCM and has been highly impressed with the performance of the EX5500-5 as well as HCM’s continued level of support. He said:

“The service and support we get from Hitachi is a key element to the long-term success of Meandu Mine,”

Once an excavator or truck is purchased it needs to be reliably operated for more than ten years, so ongoing product support is essential to Jim. “When it comes to HCM’s service and support on-site, it has been excellent for us. In one word, what Hitachi means to me is reliability.”

Partnership between Hitachi Construction Machinery and Stanwell

The EX5500-5 World Vintage Machine at Meandu Mine has set an example of what Hitachi mining machines are capable of including productivity, durability, and above all reliability. Thanks to the trust established so far, Hitachi Construction Machinery continues to evolve its solutions in partnership with Meandu Mine – for example, the development of Autonomous Haulage System (AHS) – further improving site safety and operational efficiency.

EX5500-5

| Delivery year | 2006 |

|---|---|

| Serial number | 541 |

| Operating hours | 76,896 |

| Operating weight | 518 t |

| Engine rated power (PS/rpm) | 1,320/1,800×2 |

| Bucket capacity | 29m3 |

| Feature | The EX5500-5 was the first mining excavator model equipped with an engine which complies with US Environmental Protection Agency exhaust emission regulations. It was equipped with a new cab featuring a liquid-filled anti-vibration mount, and surveillance cameras to enhance comfort, durability and safety. The EX5500-5 also featured improved sensing function, reliability, and maintainability. |

Stanwell Corporation Limited: Dealers in Australia

| 1973 | Aveling-Barford Australia |

|---|---|

| 1979 | HCM Australia Office |

| 1981 | Domino Industories Group |

| 1988 | Blackwood Hodge(Australia) |

| 1999 | Marubeni Construction & Mining Equipment |

| 1999 | Hitachi Construction Machinery Australia Pty. Ltd.(HCA) |

Source: Hitachi Construction Machinery

Copyright 2020 All rights reserved.

Copyright 2020 All rights reserved.