Composite Stands, a growing Australian start-up specialised in lightweight but extremely strong jack stands, has been employed by Hastings Deering, one of the world’s largest distributors of Caterpillar equipment, to support heavy machinery during maintenance activities.

Hastings Deering uses the innovative technology of Composite Stands for load bearing when building the new Caterpillar 796AC mining trucks at the equipment assembly pad in Mackay, Australia. This particular truck weighs in at 264 tons unladen and is used to haul coal throughout their resource-rich region. Hastings Deering is the exclusive supplier and servicer of Cat equipment and technology in that area.

Composite materials to dramatically reduce tool weight

The novel Composite Stands are patented and made from a lightweight material with superior compressive strength. They are considerably lighter than their comparable counterparts which are traditional steel jack stands. This makes it possible for one person to maneuver, compared with two people and a forklift when using heavy steel stands.

“The ergonomics of it really intrigued me. The new technology of them — I thought that’d be value adding for a brand like Cat, and Hastings Deering.”

said Paul Carman, foreman at the Hastings Deering assembly pad in Mackay, adding,

Hastings Deering Australia receive the Cat 796AC mining trucks in parts and assemble them at the Mackay outdoor assembly pad before delivery to massive coal mines in the Queensland Bowen Basin. Mackay is one of only a few locations in the world where the 30-foot-wide trucks are assembled. The trucks are almost 26 feet tall and run 52 feet from nose to tail.

In Australia, as in many parts of the world, all mobile vehicles and equipment must be supported by stands or ramps when they are being built or maintained. Jack stands are an essential item in vehicle and equipment maintenance workshops all over the world.

Hastings Deering engage eight jack stands to elevate each Cat 796AC mining truck during its build. They build several at a time and share the jack stands with other units, including the mine shop, at the Mackay facility. With Composite Stands being approximately half the price of the conventional alternative, Carman said he was able to buy enough to build two Cat 796AC trucks, compared to only buying enough for one build when buying from the competition.

That is a truckload of value.

Improved health and safety outcomes for workers

As well as bringing labor, time and cost efficiencies, the lightweight characteristics of Composite Stands make them safer for technicians to use, reducing risks associated with manual handling in positioning and storing. Manual handling is the most common cause of work-related injuries with significant direct and indirect costs.

“They are a game changer,” said Carman, adding safety of workers at Hastings Deering is paramount. And, he said, the technicians love using them.

Another plus for Composite Stands in Carman’s book is its streamlined design:

“We get scored on contamination control. The stands are quite easy to keep clean.”

Composite Stands complete product range includes various sizes and capacities. There are also accessories, including a placement-trolley and storage solutions.

Their heaviest rated stand is designed to hold 82.5 tons (165,000 pounds) and weighs less than 187 pounds. It is 40 inches high. The smallest capacity stand bears 8.8 tons, weighs less than 7 pounds and measures 5.6 inches tall. Height adjusting is also an option, in some cases up to 4 inches using inserts without pins and latches for safer use.

The 55-ton-rated Composite Stands come in three different configurations — being T1, T2 and T3. They start from 12 inches high (weighing 36 pound) and go up to 54 inches high (weighing in at just 136 pounds). These stands all have a Working Load Limit, or WLL, that is equivalent to 110,000 pounds. They have a solid steel engagement head with a 5-inch square composite column. The fabricated steel base is CNC machined. The stands can be stored inside or out, thanks to corrosion resistant powder coating and 10-year UV vinyl wrap.

Designer and founder of the products Matthew Dow keeps the composite material he uses to make the stands secret. Dow worked with Australian university engineering schools and laboratories to develop and test the products (including University of Newcastle, NSW, and University of Southern Queensland). The Composite Stands jack stands are fully designed and manufactured in Australia.

“Maintaining jack stands in a workshop can be costly. They can be difficult to manage, not to mention time and labor intensive. Composite Stands can make a difference translating into tens of thousands of dollars a year.”

said Dow.

Corrosion resistance, durability and maintenance reduction

Dow, who managed heavy equipment fleets and maintenance in the Australian mining industry for more than 20 years, said he conceived the idea for the lightweight jacks in 2016. He said the safety and manual handling issues linked with traditional heavy steel stands led him to investigate the use of composite and alloy materials as an alternate support.

This composite material has extremely high strength to weight properties that have found their way from the aviation, aerospace and motorsport industries into more mainstream industrial uses. But it can be costly to manufacture composites.

“The essential innovation was to devise the use of a continuous pultruded moulded composite section, which reduces the labor inputs significantly, and combine that with the secret lay-up of composite filaments. This process is used to build the shaft, which is then combined with a base and a durable, hard steel top/cap. Everything is aimed at dramatically reducing the final product mass whilst retaining high compressive strength capabilities.”

said Dow.

“Novel and Inventive”

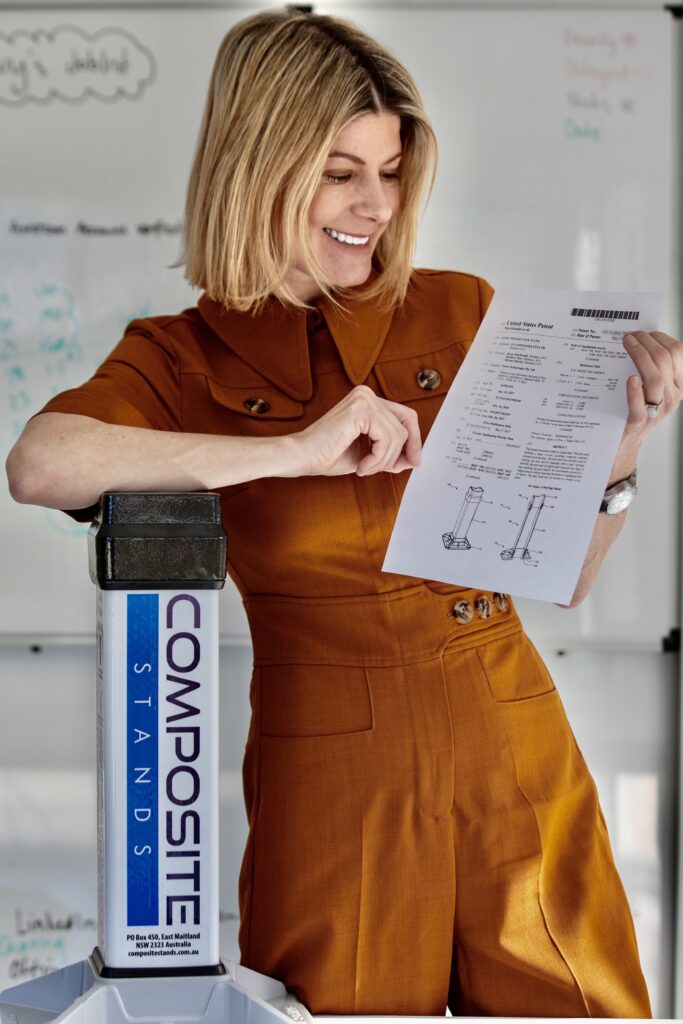

Patent applications and examinations have been entered worldwide. Dow said all the patent claims to date have been deemed “novel and inventive,” adding that this is language that endorses the strength and validity of the ultimate patent. Patents have been granted in Australia, Europe, South Africa, and most recently in the United States (in July 2021).

The products meet relevant production and manufacturing standards, including Australian Standard AS 2538:2016 for vehicle support stands, and AS 2693:2007 for vehicle jacks. Australian Standards generally meet the highest criteria in the world, and align with those of Europe and the US.

Copyright 2020 All rights reserved.

Copyright 2020 All rights reserved.