FPT Industrial, the Iveco Group brand dedicated to the design, production, and sale of low-environmental impact powertrains, exhibited at the 2024 Offshore Technology Conference, the event that has been bringing together offshore energy companies and professionals from around the world since 1969, which took place at NRG Park in Houston, TX, from May 6th to 9th 2024. FPT Industrial showcased a selection of its industrial engine portfolio at its stand.

These are a representation of its full line-up of 2.8 – 16 l (50 – 644 hp) Tier 3, Tier 4 Final and Tier 4F/Stage V engines for off-road equipment and the brand’s marine engine portfolio of 6.7 – 16 l (300-1000 hp).

These engines support various oil and gas equipment (mud pumps, mixing buckets, water pumps etc.) and can be combined with industry-specific options, such as different transmission adaptations, air compressors, PTO drives, and more. By choosing FPT Industrial, oil and gas industry companies can consolidate into one engine provider, thereby reducing their operational complexity.

“We are introducing FPT Industrial to the oil and gas industry, highlighting our strength in off-road and marine engines to power all kinds of equipment and light-to-medium commercial vessels. As one of the largest powertrain companies worldwide, FPT Industrial is a brand with over 100 years’ experience developing engines to fit equipment manufacturers’ specific needs. In the US, we are best known for working with CASE, New Holland, CAT, and Mercury, along with many others.”

said Braden Cammauf, Vice President of Commercial Operations at FPT Industrial.

Patented Technologies Making the Difference

FPT Industrial’s patented, DPF-free HI-eSCR technology for Tier 4 Final compliance requires no regeneration, thereby maximizing uptime while also meeting the most challenging applications and reducing operating costs. For compliance with Tier 4 Final/Stage V, the most demanding emissions regulations, FPT Industrial offers the HI-eSCR2 after-treatment components packed in a compact and fully enclosed structure, maintenance-free for the life of the engine.

Patented electronically controlled exhaust flap maximizes performance under low-temperature, low-load conditions, avoiding the need for additional load banks. Improved exhaust gas temperature control speeds up SCR light-off in the cold part of the emission cycle.

All FPT Industrial Stage V and marine electronic engines are fully compatible with diesel and paraffinic/renewable fuels, such as HVOs. In combination with FPT Industrial’s patented ATS technology, customers obtain the perfect low-emission, sustainable solution. Marine engines are also available in hybrid electric configurations.

Alternative Powertrain for On-Road, Off-Road, Marine and Power Generation Segments, With Power Output from 55 to 735 kW

FPT Industrial is developing alternative and sustainable powertrain solutions to meet its customers’ current and future business needs in pursuing decarbonization, leading the way in the energy transition, and reducing global emissions.

The company is focusing on research into alternative propulsion and applications for natural gas, biomethane, electric, hydrogen fuel cells and ICEs, as well as hybrid solutions. With over 20 years of experience and more than 90,000 units sold globally, FPT Industrial is introducing natural gas and methane technology in on-road and off-road segment applications. As of October 2022, FPT Industrial began producing ePowertrains, battery packs, and battery management systems for HCVs, LCVs and buses, as well as for the new Maserati 100% electric GranTurismo Folgore super sports car. In addition, FPT Industrial is field testing a 13-liter hydrogen ICE in a Prinoth snow groomer, confirming its commitment to widening its zero-emission solutions portfolio.

FPT Industrial Engines on Display

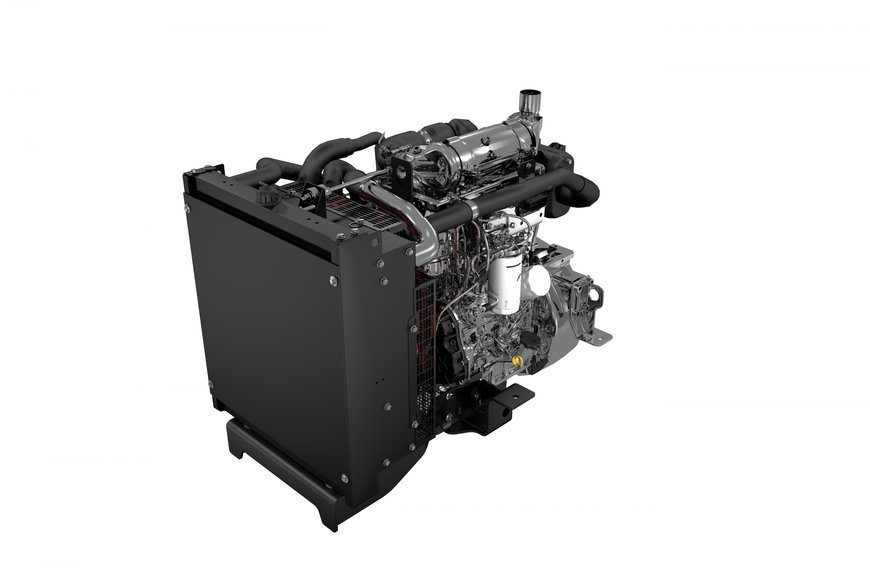

The F28

The F28, a modular, highly compact engine that offers the performance of a 3.4 l engine in a 2 l footprint, meeting the need for high power in a smaller space. The F28 PowerPack delivers best-in-class performance in an extremely compact and pre-validated package, including all key after-treatment components, thus simplifying the overall installation phase. Oil change intervals of 600 hours contribute to further lowering operating costs.

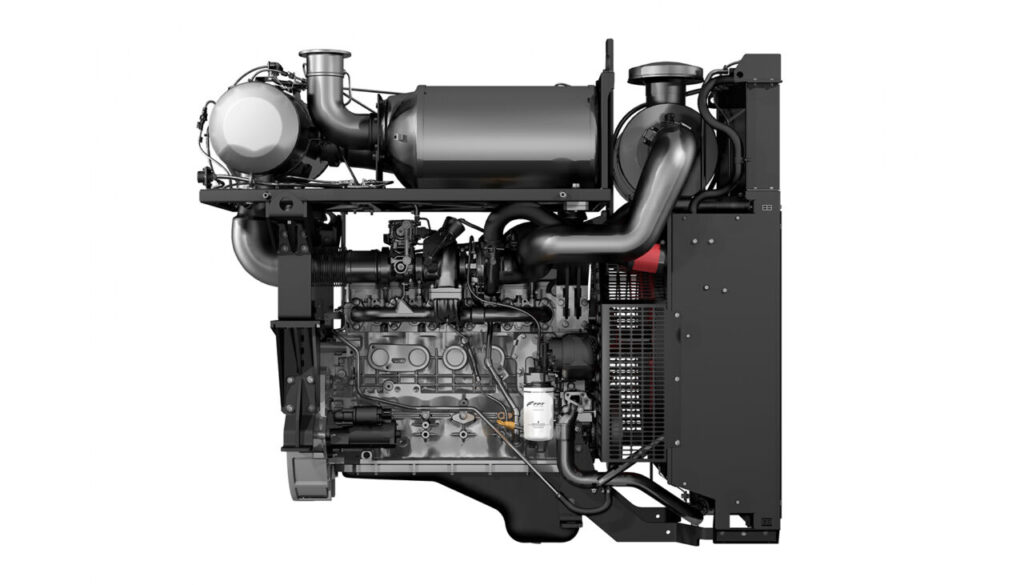

The N67 Tier 4F/Stage V Powerpack

The N67 PowerPack is developed to meet the most demanding customer requirements in a compact footprint. The maintenance-free ATS Pack is a pre-assembled, pre-wired and pre-validated solution for flexible, fast, and easy installation and labor savings. The 600-hour service interval minimizes downtime, and FPT Industrial’s “for life” maintenance-free technology guarantees maximum uptime. A range of options such as alternators, starter motors, water and air preheating, and different urea tank sizes provide further flexibility for customer installations.

C16

The Cursor 16 is the flagship of the Cursor range, with its 15.9-liter displacement delivering the performance of an 18-liter engine in a 16-liter package. High torque availability ensures fast load response, maximizing in-field productivity. Awarded the Diesel of the Year on its debut, the Cursor 16 has proven to be a strong, reliable, yet compact solution with a leading power-to-weight ratio (0.5 hp/kg).

Marine C16 1000

FPT Industrial’s marine engine lineup from 6.7 l – 16 l for recreational and commercial vessels is EPA Tier 3 certified. The Marine Cursor 16 1000 on display provides low cost of ownership technology, with ratings specifically focused on low fuel consumption and low vibration. Renowned as a compact, quiet, reliable marine engine, it is ideal for light- and medium-duty applications. A wide range of options as front PTO, rear PTO SAE-B, marine type approval, control systems, multifunction panels are available. FPT Industrial’s best-in-class 600-hour service interval maximizes uptime and lowers overall operating costs. The C16 1000 and the C16 600 are available in both keel-cooled and heat exchange configurations.

Copyright 2020 All rights reserved.

Copyright 2020 All rights reserved.