Doosan Infracore North America, LLC, is launching its next-generation wheel loaders, the -7 Series, in the U.S. and Canada. All-new redesigned cabs with first-class comfort features, increased bucket capacities and new, fuel-saving technologies are highlights of this next generation of Doosan wheel loaders.

Seven models of the new Doosan -7 Series wheel loaders, with standard bucket capacities between 3.7 and 7.6 cubic yards, are available now. Five additional Doosan models with bucket capacities between 2.6 and 3.3 cubic yards are planned to launch in early 2022. Wheel loaders launching in 2022 will include the popular tool carrier iterations for two models.

“While we have made enhancements to our wheel loaders during the past 15 years, this is a significant milestone in the Doosan product,”

says Aaron Kleingartner, dealer and product marketing manager.

The new -7 Series wheel loaders represent more than a decade of research and development, as well as incorporating feedback from our customers. The next generation of Doosan wheel loaders easily competes with any machine available today.

New Look and New Cabs

A new, award-winning exterior design is likely the first feature customers will notice about the Doosan -7 Series wheel loaders. To do their best, most focused work, operators require comfortable environments, intuitive controls and innovative technologies. With relocated controls for more efficient use, improved visibility and added technologies operators can now maximize their work.

The completely redesigned, more comfortable and quieter cab is a close second.

- The new wheel loader cab layout has relocated important and frequently used controls for easier, more intuitive use. All Doosan -7 Series wheel loaders have the same control setup, so operators won’t miss a beat when moving from machine to machine.

- For improved visibility from the cab, the total glass area is 14% larger than prior models and a full glass door improves visibility on the left side. Large mirrors extend the operator’s view to the side and rear of the machine. A standard rearview camera provides an additional view of the machine’s surroundings and appears on the 8-inch Doosan Smart Touch display. Operators can raise or lower the display to a comfortable height without tools.

- The heating and cooling system is redesigned from previous Doosan wheel loader generations, with new outlet locations to optimize air flow in the cab. Legroom is increased from prior generations, and additional in-cab storage has been added near the USB charging port.

- Electric steering is available as an option for select -7 Series models. In models with this feature, the electronic joystick, which operators can customize to their sensitivity preference, is comfortably integrated into the left armrest. The controls can be customized to the operator’s sensitivity preferences.

“It’s become increasingly difficult for our customers to hire heavy equipment operators,” Kleingartner says.

Our investments in operator comfort provide an exceptional cab that makes it a pleasant experience for long days in the cab. We’re convinced that cabs today are among the most comfortable operating stations, which we hope will help our customers retain their operators.

Increased Bucket Capacities and New Features To Protect Machine Uptime

- Bucket capacities for select models are 7% greater than prior models. These select Doosan models include the DL320-7, DL380-7, DL480-7 and DL580-7. The increased capacity can provide faster, easier loading in fewer passes.

- To enable these greater capacities, these beefed-up models feature stronger, larger axles and a strengthened box frame. Large center bearings and self-centering, double-tapered roller bearings distribute vertical and horizontal loads over a larger area. The bearings have dust seals and covers and are vented to prevent grease overfill.

- The new axles offer better braking capacity to extend the lifetime of the brake discs. Other improvements that enhance durability include a new radiator with fin spacing that is 40% wider than previous generations. This wider spacing makes the radiator less prone to clogging and easier to clear of dirt, dust and other large debris.

- A standard reversible fan, adjustable from the Doosan Smart Touch screen, further improves cooling system performance. The fan is hydraulically driven with variable speeds that are proportional to the operating temperature. It easily folds out of the way for cleaning the radiator. This can be particularly useful in applications like agriculture and forestry.

- An automatic lubrication system is a new factory option for Doosan -7 Series wheel loaders, and it includes full warranty coverage. The system delivers grease at the middle of the pins and bushings for better distribution.

Loaded With Smart Technologies

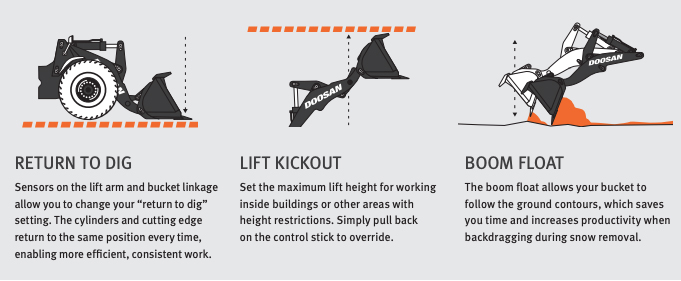

Doosan -7 Series wheel loaders are designed with standard technology features that owners and operators can use to make meaningful improvements to the productivity of their operations. Technologies standard on Doosan -7 Series wheel loaders include:

- DoosanCONNECT telematics makes it easy for owners to monitor their Doosan fleet and manage maintenance to reduce operating costs. Using a smartphone, tablet or computer, owners can check machine location, operating hours, fuel usage, engine idle versus work time, error codes, engine and hydraulic oil temperature, customize alerts to your schedule, use data to train your team for maximum productivity and more. The data is uploaded automatically to the DoosanCONNECT online system using dual-mode communications (cellular and satellite) for maximum coverage. You can check on machine status from anywhere using the DoosanCONNECT website and mobile application. Your dealer can also see your equipment status to notify you when it’s time for service.

- Situation Awareness Technology automatically monitors the machine’s activity and adjusts the wheel loader engine’s output to match real-time requirements of the hydraulic system and drivetrain.

- The Doosan Smart Guidance System analyzes operator driving habits and provides tips during operation on the Doosan Smart Touch display to improve their efficiency.

- An improved Load Isolation System improves wheel loader stability while moving, which can reduce cycle times, increase productivity and boost fuel efficiency.

- The new Doosan Smart Load weighing system tells the operator the weight of material in the bucket. All menus and settings are integrated into the Doosan Smart Touch screen.

- The Doosan Smart Key is a key fob that can unlock the cab and allows the push-button engine to start.

Kleingartner says:

“We offer a wide range of wheel loader models to meet our customers’ needs. Our 12-model lineup provides customers a variety of horsepower and capacity offerings to best match their applications. Customers operate Doosan wheel loaders in agriculture, construction, recycling, mining, snow removal and forestry applications. Across these applications, customers can expect Doosan wheel loaders to be productive and durable.”

![[Job Story] Liebherr LB 30 Unplugged Drill Rig Put to the Test in Canada’s Icy Winter](https://www.heavyquipusa.com/wp-content/uploads/2024/05/liebherr-lb-30-unplugged_2_96dpi-218x150.jpg)

Copyright 2020 All rights reserved.

Copyright 2020 All rights reserved.