Continental has introduced a system that measures material volume and position on conveyor belts in real time which helps operators reduce the risk of overloading or spilling material from the belt. It has also introduced CONTI SurfaceProtect, a laser-based system that continuously monitors the surface of flat fabric or steel cord conveyor belts in industrial and mining applications.

CONTI LoadSense

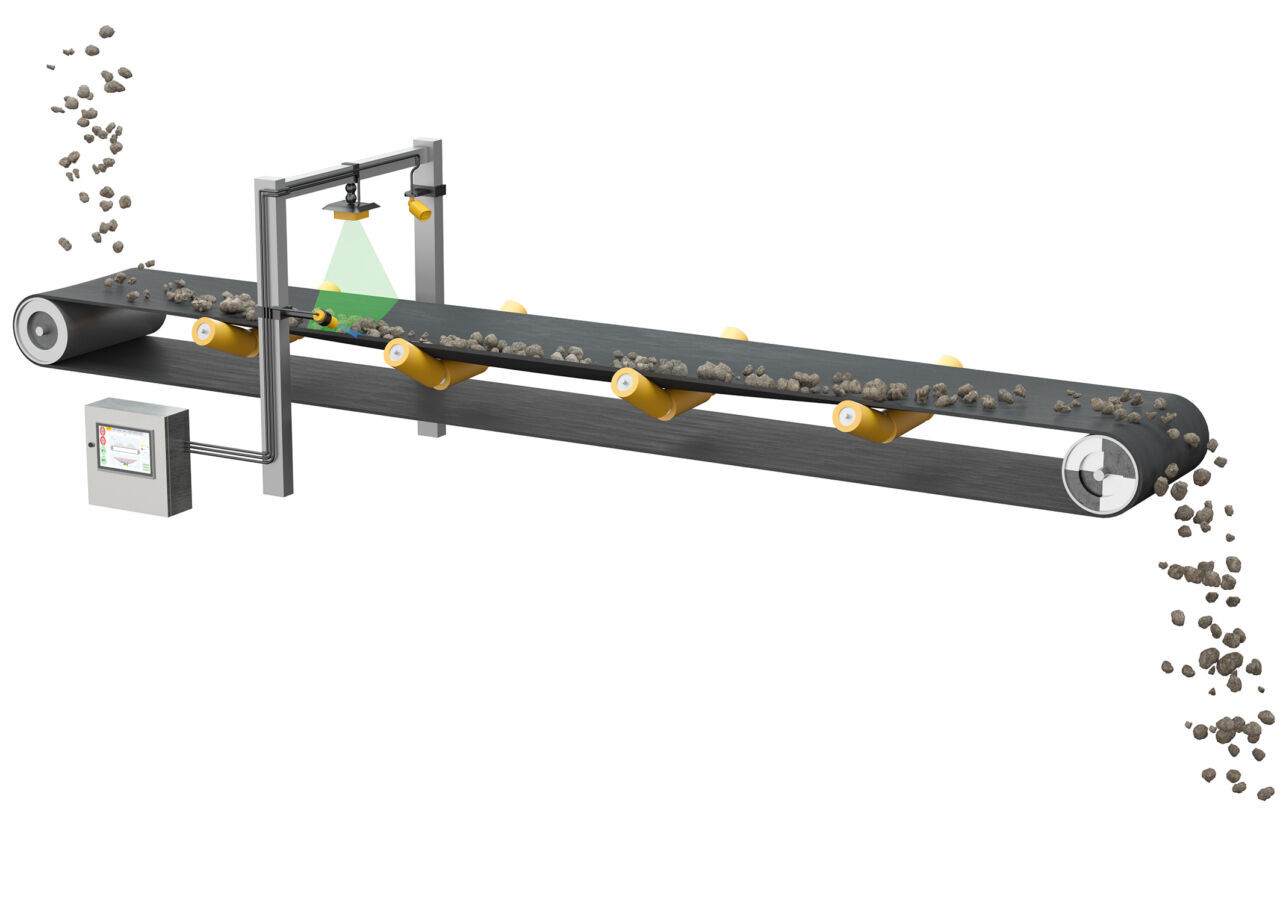

CONTI LoadSense combines radio wave detection and ranging (2D radar) along with ultrasonic sensors to calculate the volume and position on the belt of the material being conveyed. The system scans the material and conveyor belt from different angles to determine the position of the load and the belt. From the data collected, the system can accurately calculate the volume of material being conveyed.

Real time monitoring allows measurable increased productivity

CONTI LoadSense monitors the load’s center of gravity on the belt, as well as load distribution along the entire conveyor length, 24/7.

CONTI LoadSense monitors the load’s center of gravity on the belt, as well as load distribution along the entire conveyor length, 24/7.

“The risk of spilling material is determined by monitoring the belt edge position in relation to the profile of the material. Data correlation is used to calculate volume flow, monitor overrun, and belt skew. Belt speed is measured to track belt and load position”

according to Patrick Raffler, who is responsible for Digital Solutions for the Conveying Industry at Continental.

“Having this real time monitoring allows operators of stone, sand, or gravel quarries to measurably increase productivity. At one German gravel plant, operators were able to increase output by up to 100,000 tons per year after employing the CONTI LoadSense radar-based monitoring system. The plants run more economically due to the automatic material detection, and the system reports deviations before losses occur, preventing expensive clean-up costs,”

says Raffler.

Compared to traditional monitoring technologies such as lasers or belt scale, CONTI LoadSense’s radar sensor requires less maintenance and is less sensitive to external influences like dust, rain, and vibrations.

Moving monitoring and reporting online

CONTI LoadSense can be connected to the Conti Cloud. This means that the recorded data can be processed in a graphic-based format for the end customer via a web service or the Conti+ 2.0 online service portal and the associated Conti+ 2.0 app.

CONTI SurfaceProtect

The CONTI SurfaceProtect system provides an early warning when belt maintenance or replacement will be required. This allows for planned, orderly belt service, which is faster and less costly then repairing belts after a catastrophic failure.

“With the CONTI SurfaceProtect system, industrial and mining belt conveying applications can be monitored on a constant basis, reducing the need for manual reviews of the belt condition. The belt profile information can be used to determine the remaining life of the belt and identify the exact location and severity of wear and damage. The SurfaceProtect system is especially useful in applications where conveyor belts are difficult to access or inspect, allowing for remote examinations of the belt condition. By monitoring over the entire belt life cycle, operators are able to maximize belt life,”

notes Anthony DiGiacobbe, Continental Communications Manager, North America.

The CONTI SurfaceProtect top cover monitoring unit projects a laser line on the running conveyor belt surface as an optical sensor records the shape and position of the laser line to create a digital map of the belt cover surface topography.

The CONTI SurfaceProtect bottom cover monitoring unit provides overall belt shape monitoring and optical monitoring for longitudinal belt rips without the need for rip detection inserts in the belt. The bottom unit includes automatic alarm and belt stop functions.

Copyright 2020 All rights reserved.

Copyright 2020 All rights reserved.