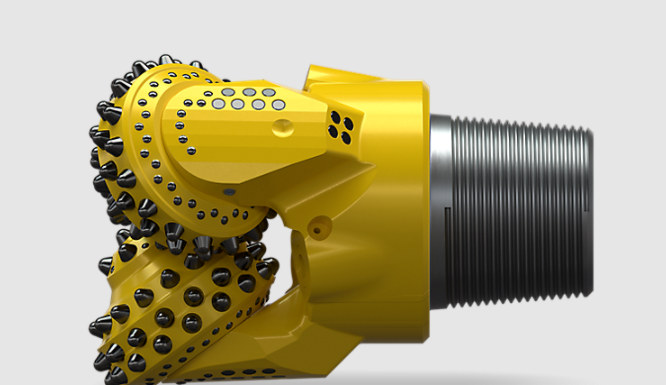

Epiroc is now launching Omega S - the new tricone rotary drilling bit.

A single sealed bearing bit that, when the seal eventually wears off, transforms to an air bearing bit thus increasing drilling performance with up to 30 percent...

The drills conventionally used in quarries are designed to operate at a bench depth of about 12-15 meters. Trying to penetrate much deeper can cause Down-The-Hole and tophammer drills to deviate, creating accuracy and potential safety problems.

So when drilling...

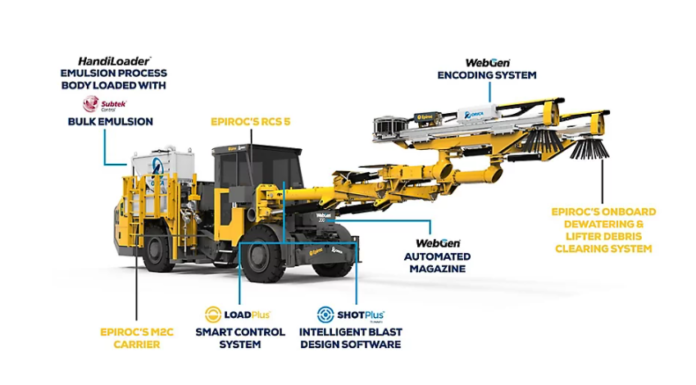

Epiroc and Orica have successfully co-developed a prototype of the world’s first semi-automated explosives delivery system.

Customers in the underground mining industry can look forward to safer, efficient and more productive development blasting as early as the end of 2021,...

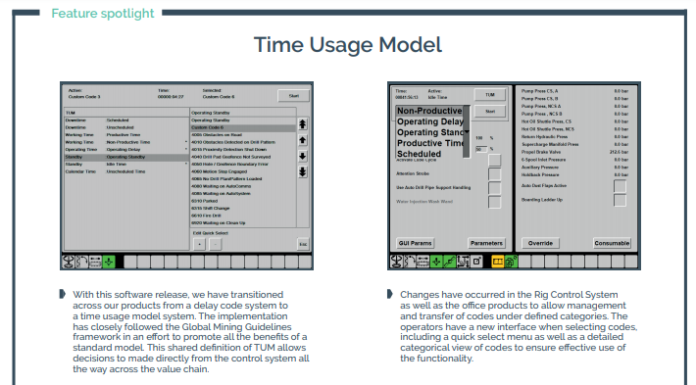

Epiroc, a leading productivity partner for the mining and infrastructure industries, introduces RCS 4.20, a software update to its proprietary Rig Control System, taking the next evolutionary step in data-driven mining. RCS 4.20 includes a range of general improvements and...

In northern Finland, close to the Arctic Circle, Agnico Eagle Finland is operating the Kittilä mine, the largest gold mine in Europe.

In the harsh winter of Lapland, Epiroc’s battery-powered machines, the Boomer E2 Battery, Scooptram ST14 Battery and Minetruck...

As mining companies continue to strive for sustainable productivity and zero emissions, the fast evolution and development of different options within the field of battery technology can be extremely challenging.

Batteries as a Service hits the mark.

“A key component to...

Robot trucks have been hogging the headlines in mining’s new technology rush, but auto-drills are arguably the key to unlocking major value on a mine site.

“If the drills don't perform, the trucks are going to run empty,” says Epiroc...

Epiroc has decided to move away from the concrete spraying business and will phase out its concrete spraying line within 2020.

Epiroc develops and manufactures six products within the concrete spraying line in its product companies in Örebro, Nashik, and...

Epiroc’s two annual awards recognize close collaboration with a mining company that strengthened the customer’s productivity through automation as well as the development of battery-electric equipment that brings multiple benefits to the mining industry.

The United in Performance Award honors exceptional customer...

Epiroc introduces HATCON, a remote monitoring device for breakers and drum cutters that keeps track of location and operating hours to improve efficiency and safety.

The cloud-based platform My Epiroc gives customers notifications about service, create task lists and provides a...

![[Job Story] Epiroc’s SmartROC C50 at Work on the South Shore of Montreal, Canada](https://www.heavyquipusa.com/wp-content/uploads/2020/12/epiroc-14.12-646x385.png)

![[Video] Epiroc Completes ‘Batteries as A Service’ Agreement with Vale](https://www.heavyquipusa.com/wp-content/uploads/2020/07/epiroc-696x385.jpeg)

Copyright 2020 All rights reserved.

Copyright 2020 All rights reserved.